Capabilities

Spiral Welding

- Diameters from 1/2 ” to 8.00”

- Thicknesses from .024 to .165

- Almost any length

- See a diameter to wall thickness chart

Straight Welding

- Diameters from 1/2 ” to 3.25”

- Thicknesses from .030 to .105

- Lengths up to 24ft

Special Finishes

- Centerless grinding

- Plating

- Zinc Plating

- Nickel Plating

- Electropolishing

- Grit Blasting

- Glass Bead

- Jet Mag

- Steel Shot

- Deburring

- Buffing

Perforation Patterns

Perforation Patterns

- Open areas up to 60%

- Hole diameters from 0.060 and to 1″

- Staggered, straight patterns

- Custom patterns

Secondary Operations

- Support rings

- End forming

- Special fittings welled to ends

- Grinding

- Polishing

- MIG/TIG Welding

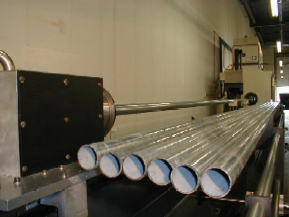

Equipment & Machinery

- 5 Perforating presses

- 6 Deburring machines

- 3 Lathes

- Tube mills

- 3 Tube lasers

- 7 Spiral tube winders

- 4 Cutoff saws

- 2 Milling machines

- 2 Surface grinders

- 3 Centerless grinders

- OD Polisher

Customer Service

- Prototypes

- Small Quantities

Laser Tube Cutting

With our Laser Tube Cutting System we offer tight tolerances and more consistent cuts on our perforated tubing and can fabricate tubular components from round, square, rectangular or oval tubing. Our laser is capable of handling tubing to 24 feet in length and 6 inches in diameter and can produce completed parts in one process – both ends and all internal features are cut in one pass.

With our Laser Tube Cutting System we offer tight tolerances and more consistent cuts on our perforated tubing and can fabricate tubular components from round, square, rectangular or oval tubing. Our laser is capable of handling tubing to 24 feet in length and 6 inches in diameter and can produce completed parts in one process – both ends and all internal features are cut in one pass.

With the flexibility and excellent edge quality of laser cutting, our laser is ideal for customers who require tubular parts in quantities from a few parts to tens of thousands. It allows for a variety of shapes and features to be cut. The ends can be profiled in any number of ways, including fishmouth, angle cuts, or notched. It cuts square or rectangular tubes as well.

Corner notching can be done more easily than with a mill. Laser processing leaves little or no burr to clean up.

Corner notching can be done more easily than with a mill. Laser processing leaves little or no burr to clean up.